126. Just-in-Time or Just-in-Case? | ’及時供應’ 還是 ’以防萬一’?

– Musings of Dr. Jamie C. Hsu, 11.3.2021

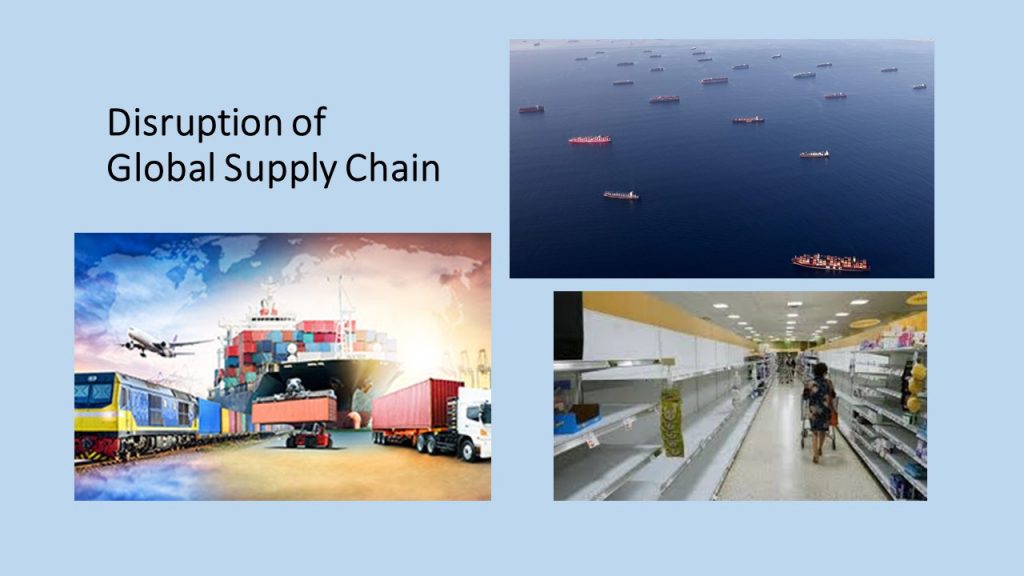

You see it, you hear about it, and you experience it: the disruption of the global supply chain. The store shelves are empty, the shipping ports are jammed with huge cargo ships, and prices are escalating. This unprecedented phenomenon is happening globally. No one can escape its impact. What caused all this? The primary culprit is undoubtedly the pandemic, which has caused labor shortages, lockdowns, and transportation disruptions.

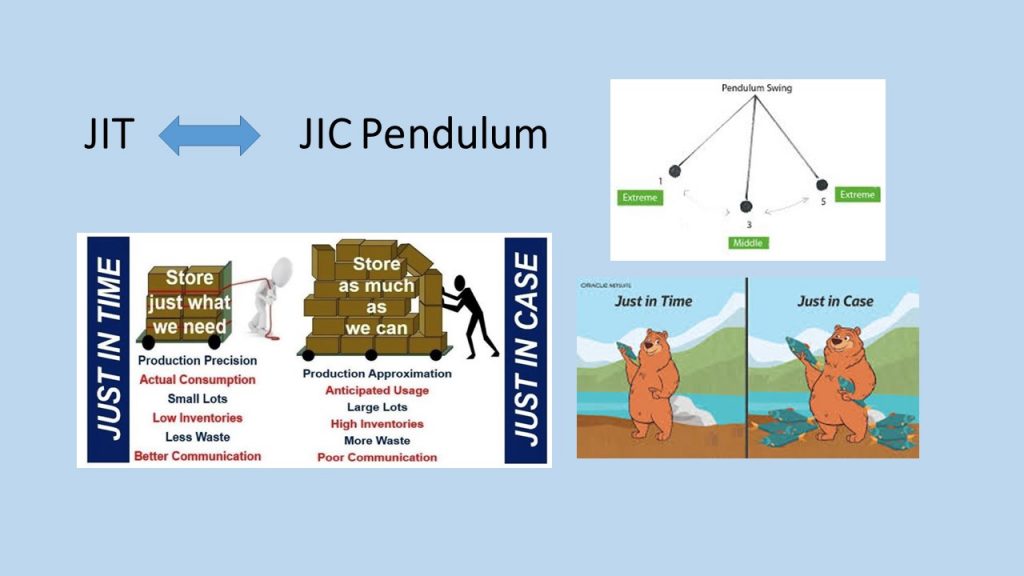

Another reason is the global Just–in-Time production system, which has been made famous and popular by Toyota and mimicked by many other manufacturing companies. At GM, over the last few decades, we studied and analyzed the benefits and principles of JIT production. Compared to our old mentality and culture of Just-in-Case (JIC), this new JIT lean production system showed us a lot of benefits. It saves capital, inventory, defects, and waste. It makes the whole supply chain visible and controllable. We all learned and implemented this JIT production system and even applied its philosophy to the non-production areas. We changed from the rich man’s Just-in-Case habits to the poor man’s Just-in-Time operation.

Who would have anticipated the unprecedented global pandemic which is causing huge disruptions in every corner of the global supply chain? Suddenly, the weak links in the global supply chains are showing up everywhere, from raw materials to labor, production, shipping, stocking, and retailing. On the other end, this supply disruption has caused a major shift in the demand side. End users are embracing the JIC practice and beginning to hoard materials and goods, causing even more stress in the supply chain.

The pandemic has caused the pendulum to swing from JIT to JIC. The conflicts of these two very different systems are causing the current supply and demand chaos. It will take some time for the global system to find the right equilibrium and begin to function smoothly again. Maybe a better system will emerge that is synchronous, agile, sustainable, and utilizes the best AI, automation, 5G, and digital technologies.

We can wait for such a system, anticipate it, or better yet, help to create it. Let us make this JIT-JIC crisis an opportunity for innovative solutions.

’及時供應’ 還是 ’以防萬一’? (2021/11/03)

-作者 許俊宸博士

-中譯 薛乃綺

你看到了、聽到了、也正在經歷到:全球供應鏈斷鏈來了!商店貨架上空無一物、運輸港口擠滿了巨型貨船、運費成本不斷飆漲。這種前所未有的現象正在全球各地發生,沒有人能擺脫它的影響。究竟是什麼原因造成這一切?疫情無異是造成勞動力短缺、封鎖、運送中斷的罪魁禍首。

另一個原因是全球及時生產与及時供應(JIT)系統,它因為豐田汽車而聲名大噪,也被許多其他企業複製採用。在通用汽車裡,過去幾十年中,也研究跟分析了JIT系統的優點跟原理。這跟我們過去以防萬一Just-in-Case (JIC)的心態以及文化比較起來,新的JIT精實生產系統展示更多的優點。它可以節省資金、庫存、缺陷以及浪費;它使整個供應鏈可視化及可控制。我們都學習並實施了這種JIT生產系統,甚至將這個理念應用到非生產系統中。我們已經從有錢人的Just-in-case以防萬一的習慣,轉變為窮人的Just in Time及時生產和供應的操作。

誰想得到史無前例的全球大流行病,還會造成全球各個角落的供應鏈發生中斷的狀況。突然間,全球供應鏈的薄弱環節無所不在,從原物料到勞動力、生產、運輸、庫存以及零售。

另一方面,這種供應鏈中斷,也導致需求面發生重大轉變。終端用戶採用JIC的做法,開始囤積物資,對供應鏈造成更大的壓力。

而疫情讓這種情形像鐘擺一樣,從JIT移動到JIC。這兩個截然不同系統的衝突,正導致當前的供需系統發生混亂。全球系統需要一些時間才能找到合適的平衡點,並重新開始穩定運行。也許會出現一個更好的供應系統,更靈活、還会有可持續性、並且可以利用最好的人工智能、自動化、5G及數位技術来增加这系統的应变力。

我們可以等待這樣的系統,預測它的发生,或者更好地幫忙来創造它。讓這個JIT-JIC危機成為創新解決方案的好機會。